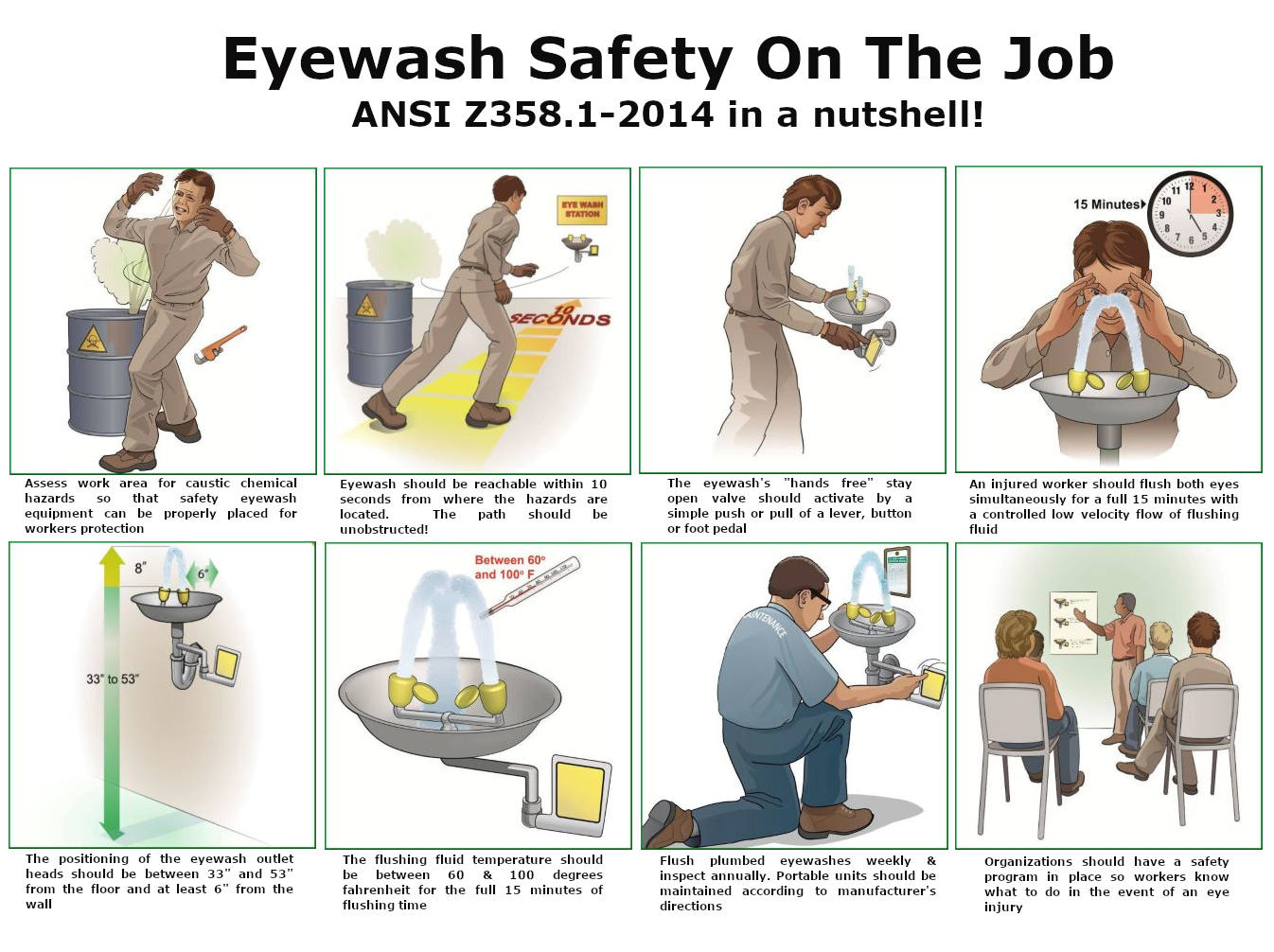

EYEWASH SAFETY ON THE JOB

ANSI Z358.1-2014 in a nutshell

- Assess work area for caustic chemical hazards so that safety eyewash equipment can be properly placed for workers' protection.

- Eyewash station should be reachable within 10 seconds from where the hazards are located. The path to the eyewash station should be unobstructed.

- The eyewash's "hands free" stay open valve should activate by a simple push or pull of a lever, button or foot pedal.

- An injured worker should flush both eyes simultaneously for a full 15 minutes with a controlled low velocity flow of flushing fluid.

- The positioning of the eyewash station outlet heads should be between 33" and 53" from the floor and at least 6" from the wall.

- The flushing fluid temperature of the eyewash station should be between 60 & 100 degrees fahrenheit for the full 15 minutes of flushing time.

- Flush plumbed eyewashes weekly and inspect annually. Portable units should be maintained according to manufacturer's directions.

- Organizations should have a safety program in place so workers know what to do in the vent of an eye injury.

The information on this page is an original copyrighted article. We welcome you to link this page from your website. However, copying this article or illustrations in whole or in part is strictly prohibited.

Disclaimer: We have provided this article as general information on the use of this article. We make no claims as to the accuracy or completeness of the information as it may apply to an infinite amount of conditions and situations. It is the responsibility of the person or persons reading and using this information to refer to the instructions and information provided by the manufacturer in the product package before testing or using this product. Users of this information agree to hold Select Safety Sales LLC harmless from liability of any kind relating to the use of this information.